- Joined

- Mar 3, 2005

- Messages

- 8,205

- Points

- 5,213

In this guide I will show you guys how to DIY some ground cables for your car. You can choose to buy ready made sets from shop but it's more fun if you can make them yourselves save you the extra bucks and get to know your car more.

What you need?

1. Cables

The cable is the important part. You need to buy pure copper cables as higher copper % better conductivity. The Sizing is up to you and you also need to take into consideration is the cable easy to work on. On my case, I didn't buy the cables from shops. The cables I got was salvaged from a broken down heavy industry use AC motor with 20hp 415V 3 phase 3000rpm @50Hz. I took the cables off from the motor since I notice they were good stuff.

2. tools you need.

3. Materials

Cable lugs (in the pictures are 25mm cable lug with silver coating)

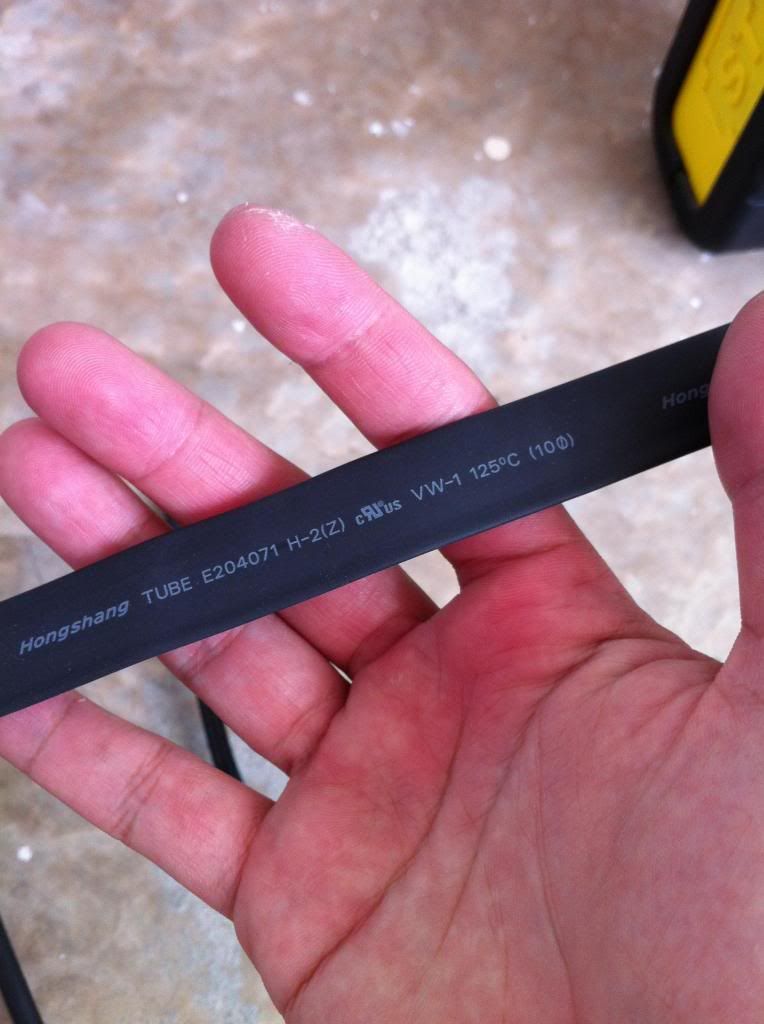

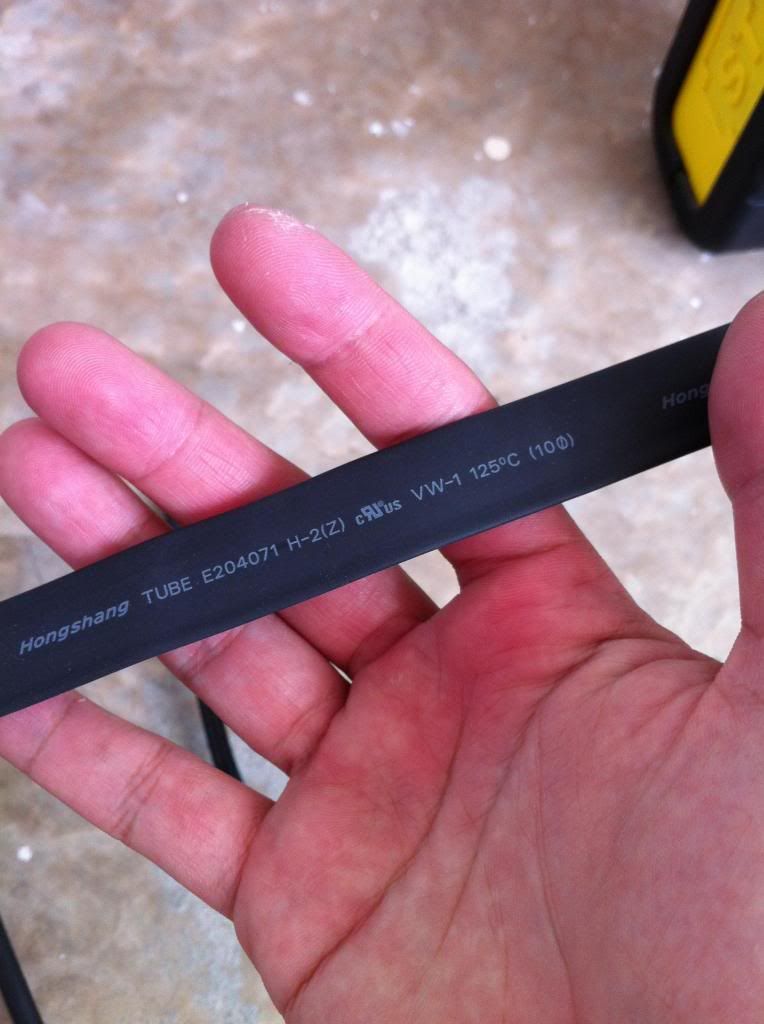

Heat shrink tube

Some size M6 bolts & Nuts (Optional if you need to add new extra earth point)

Step 1

Measure the distance that you going to put your DIY earth cable, then cut the cable to the length.

Slip the cable lug over the un-strip cable to measure how much insulation to strip.

Step 2

Strip the insulation off the measured line

Step 3

Slip in the cable lug and crimp it down with a wire crimper or a playar (best is to use crimper but I left my crimper at the office) if you use playar please crimp the wire a few more times to ensure that it is tight. You can even use a hammer to hit the end of the playar which is crimping on the cable lug. IF you like you can also heat the cable lug up with a solder gun and put in some iron solder to add grip to the cable and the lug.

Step 4

After finish crimping the lugs on both end, slide in the heat shrink tube, you can choose to put the heat shrink over the lug and the wire or the whole cable which I did. Now to make the tube shrink you need a heat gun or a hair dryer or you cooking stove (gas type with fire). For me I use my wife's saloon type hair dryer set it to max speed and max heat this will make the tube shrink and it's damn hot.

Step 5

This is the final product. It's pretty easy to make and fun to make

This is where I wire the DIY earth point. The black cable running along the fuse bot to the firewall (that's not my horn or my alarm siren I also have no idea what is that for..Hahaha) from the battery negative terminal.

I've only wire 2 cables at this time 1 as in the picture another 1 is from the alternator housing to the car body. After doing this, I can felt the reduce of throttle lag from the DBW system. Not placebo effect it actually reduced because I timed my leg on the gas and the respond of the engine. I did this on my Mitsubishi Grandis and I've also did this on my FLX.

So enjoy the DIY

What you need?

1. Cables

The cable is the important part. You need to buy pure copper cables as higher copper % better conductivity. The Sizing is up to you and you also need to take into consideration is the cable easy to work on. On my case, I didn't buy the cables from shops. The cables I got was salvaged from a broken down heavy industry use AC motor with 20hp 415V 3 phase 3000rpm @50Hz. I took the cables off from the motor since I notice they were good stuff.

2. tools you need.

3. Materials

Cable lugs (in the pictures are 25mm cable lug with silver coating)

Heat shrink tube

Some size M6 bolts & Nuts (Optional if you need to add new extra earth point)

Step 1

Measure the distance that you going to put your DIY earth cable, then cut the cable to the length.

Slip the cable lug over the un-strip cable to measure how much insulation to strip.

Step 2

Strip the insulation off the measured line

Step 3

Slip in the cable lug and crimp it down with a wire crimper or a playar (best is to use crimper but I left my crimper at the office) if you use playar please crimp the wire a few more times to ensure that it is tight. You can even use a hammer to hit the end of the playar which is crimping on the cable lug. IF you like you can also heat the cable lug up with a solder gun and put in some iron solder to add grip to the cable and the lug.

Step 4

After finish crimping the lugs on both end, slide in the heat shrink tube, you can choose to put the heat shrink over the lug and the wire or the whole cable which I did. Now to make the tube shrink you need a heat gun or a hair dryer or you cooking stove (gas type with fire). For me I use my wife's saloon type hair dryer set it to max speed and max heat this will make the tube shrink and it's damn hot.

Step 5

This is the final product. It's pretty easy to make and fun to make

This is where I wire the DIY earth point. The black cable running along the fuse bot to the firewall (that's not my horn or my alarm siren I also have no idea what is that for..Hahaha) from the battery negative terminal.

I've only wire 2 cables at this time 1 as in the picture another 1 is from the alternator housing to the car body. After doing this, I can felt the reduce of throttle lag from the DBW system. Not placebo effect it actually reduced because I timed my leg on the gas and the respond of the engine. I did this on my Mitsubishi Grandis and I've also did this on my FLX.

So enjoy the DIY

thank you thank you....

thank you thank you....